Solutions for Aerospace

The aerospace industry is built on precision and powered by innovation. As the sector evolves to meet new technological, environmental, and operational demands, manufacturers face increasing complexity—from tighter tolerances and advanced materials to sustainability goals and global supply chain shifts. Success requires more than production capacity; it demands a partner who understands the intricacies of aerospace manufacturing. At Tessera, we deliver high-quality, high-performance solutions that optimize production, improve reliability, and help our aerospace customers stay competitive, efficient, and future-ready.

Industry Challenges in Aerospace

Operating in the aerospace industry requires meeting exacting standards while staying ahead of rapid market changes. From global supply chain pressures to evolving environmental expectations, these challenges can slow innovation and impact profitability. Common challenges include:

Rising Production Costs

We utilize the Plan-Do-Check-Act (PDCA) cycle to drive ongoing process optimization and ensure we adapt to evolving customer needs.

Supply Chain Disruptions

Unpredictable global supply chains can delay production, increase costs, and complicate inventory management.

Sustainability Pressures

Aerospace manufacturers face growing requirements to reduce emissions, adopt eco-friendly materials, and meet industry-wide environmental standards.

Our Solutions for Aerospace Manufacturers

We provide tailored manufacturing solutions that address these challenges head-on. With advanced capabilities in precision machining, sheet metal fabrication, and kitting and assembly, Tessera helps aerospace organizations improve performance, streamline operations, and maintain a competitive edge.

Precision Machining

Delivering aerospace components requires more than standard machining—it demands unwavering accuracy and consistency. Our precision machining capabilities support both quick-turn production and long-term contracts for commercial and defense applications. Tessera’s aerospace machining solutions ensure every component meets the industry’s highest standards for reliability and performance.

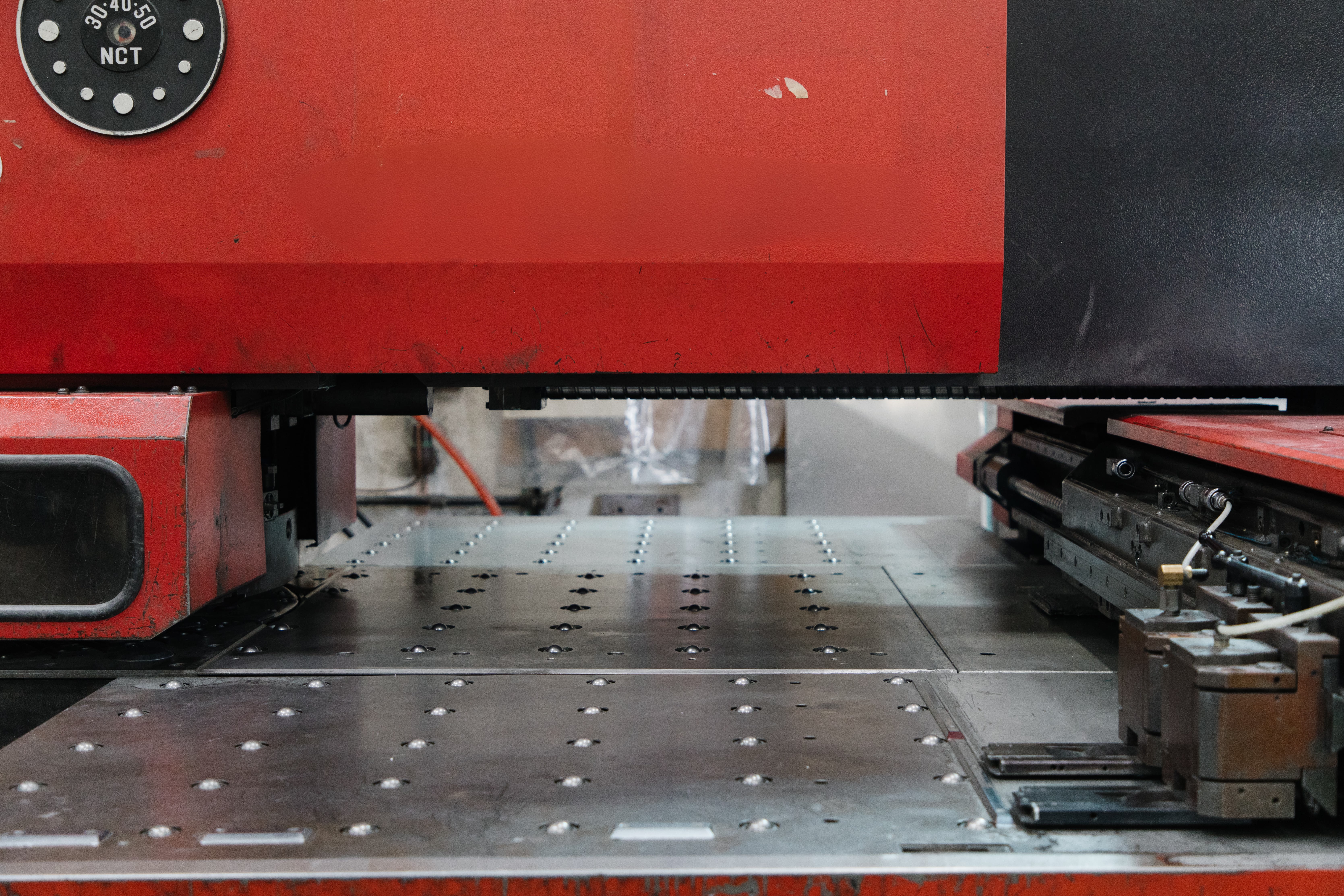

Sheet Metal Fabrication

Sheet metal components are essential to modern aerospace applications, from airframes to avionics enclosures. We use cutting-edge fabrication techniques to produce parts that are lightweight, durable, and optimized for performance. Our fabrication processes combine technical precision with quality control protocols to deliver dependable results.

Kitting & Assembly

Efficiency is critical in aerospace production. Our kitting and assembly services simplify complex assembly processes by delivering organized, ready-to-use kits directly to your production lines. By reducing assembly time and minimizing material handling, we help aerospace manufacturers streamline production and meet delivery deadlines.

Built for Aerospace Success

Tessera takes a proactive, solutions-first approach to aerospace manufacturing. We don’t just deliver parts—we provide strategies and systems that improve quality, productivity, and long-term resilience.

Operational Efficiency

We apply lean manufacturing practices, process optimization techniques, and advanced automation to improve productivity while reducing costs and waste.

Sustainable Practices

Tessera supports aerospace clients in achieving environmental goals through energy-efficient processes, recyclable materials, and responsible manufacturing techniques.

Supply Chain Resilience

We use predictive analytics, diversified supplier networks, and streamlined logistics to reduce disruptions and maintain consistent production schedules.

Let’s Build the Future of Aerospace Together

Discover how Tessera’s aerospace manufacturing solutions can help you improve efficiency, reduce costs, and achieve long-term success.